#1

Start with new rotors or cut the used rotors on a brake

finishing lathe using sharp bits and correct feed

speeds.

As always, best results will be achieved by closely

following the set-up and maintenance instructions in the

lathe owners manual. (Note: We have found the newer

style GWR

"Round Lathe Bits"

produce consistent, lower RA finishes than standard

bits)

#2

Use the new, patented

Flexible

Hone for Rotors

on both friction surfaces of the new or turned rotors,

to create and O.E. style cross-hatch.

(Note: An angle head, electric drill is highly

recommended as it's speed is more constant and

rotational torque is virtually eliminated). It only

takes about 20 seconds to "re-profile the surface" and

create the perfect bedding surface for your new pad.

Simply move the spinning tool across the surface (in and

out motion) about five times and then make one slow pass

from inside to outside, to deliver a final symmetrical

pattern. (Note: Contrary to popular belief, laboratory

testing has determined sand paper or round discs do

not produce the proper rotor finish needed to

control (slow down) the burnish of a new pad.)

#3

Thoroughly clean the friction surfaces and hat area of

the rotor with

GWR Brake-Soap

and water solution... using a hand scrub brush.

It has been proven in the laboratory that this helps to

demagnetize and then remove imbedded micro fine steel

particles significantly better than aerosol brake

cleaners. When scrubbing is finished, rinse completely

with clean water and then air dry.

#4

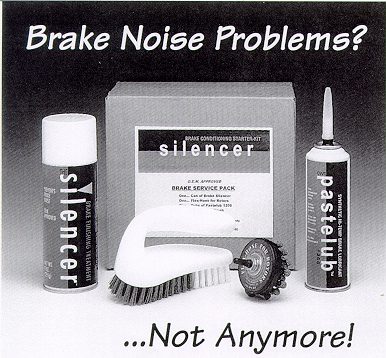

Spray a very light, even

coat of

the Silencer - Brake Conditioning Treatment

on both sides (friction surfaces) of the rotor.

Be sure to shake the can well to completely disperse the

solid particles into the synthetic carrier the Silencer

treatment uses to deliver them to the rotor. (Notes: You

don't need a lot of this product to do the job

correctly, only a light single coating of the rotor is

necessary. Additionally, no

drying time is required before assembly or

driving.)

A little freebie tip... You can spray a light

coat of GWR "Silencer" on calipers and the entire rotor,

to eliminate rusting in harsh environments or extended

winter storage periods.

It will leave a beautiful silver appearance that last

for years because it's impervious to water, snow, salt,

heat, cold and other conditions. Additionally, it does

not get sticky or effect brake action so you don't have

to remove it before putting stored vehicles into service

each season.

WARNING: Several large packaging companies have

attempted to copy the OE Approved "Silencer-Brake

Conditioning Treatment" in recent years.

What's more interesting is... most came to GWR and ask

us to private label the real Silencer for them first.

Why? Because it works, it's safe and they did not have

the expertise to do it themselves! Unfortunately for the

driving public, when we quoted them prices they all said

"you're too expensive, we can make it for about a $1 a

can!"

Well, they're right! You can make it for $1 a can. If

you leave out the real synthetic carrier, leave out the

special high pressure synthetic oils, leave out the

anti-corrosive agents, leave out the expensive moly

powder, leave out the specially shaped particulates of

aluminum and graphite, etc, etc.

As you can imagine...

these companies did go forward and make their own cheap

versions because major profits were anticipated. To

reduce the cost, they used petroleum for the carrier and

eliminated most of the other important components we

include!

The question is "can you", the consumer or shop, afford

to take a chance on these Non OEM Approved and

potentially dangerous brake products when it comes to

your own car, or that of your customers?" Worse can you

depend on chemical "packaging" companies to be experts

in the brake business???

If

you are in doubt about a product you are using or are

thinking of using, just check the ingredients listed on

the label of the can. If you find Mineral Spirits or

Stoddard Solvent listed, the product can "not" be used

on brake rotors without voiding the new pad warrantee

and making them unsafe!

Simply stated, "no product other than "the Silencer" is

a "Real Synthetic" formulation. All the copies are base

on petroleum products and lack the important ingredients

that are required to give the long lasting desired

results... no brake noise!

You

have our word, based on over 30 years in the business in

the USA and 75 years in Switzerland, none of the copies

are even close to our original Silencer product!

Neither do they share the national and international

awards, accolades, O.E.M. endorsements or safety level.

If you have been told any other brake conditioner is

equal to or better than Silencer... please call GWR and

let us know. We would like to tell you the whole story

and explain the real difference between the original and

the copies. Additionally, we'll show you why there are

safety issues involved that "will" affect you

personally. Thanks, GWR

#5

Apply

Pastelub-2400 Extreme

Hi-Temp Synthetic Dry-film Lubricant to caliper mounting

brackets, mounting bolt threads, the rust free hat area

at center of rotor (thoroughly clean before

turning if any rust is present) and any other metal to

metal contact points. Next, coat caliper piston face

(where pad backing plate contact occurs) and or the back

of the brake pad, along with any other points of contact

(guide ears, etc) with

Ceramlub-2800

Ultra

Hi-Temp Synthetic Dry-film Lubricant

(Note: Do not use low temp moly style greases (300º to

600º) or any type silicone (maximum of 400º) for any of

these applications as they will break down with heat and

pressure and generally cause contamination of friction

surfaces during this change. Note that the revolutionary

Ceramlub lubricant is far superior to all silicone type

lube products commonly used on slide pins, etc, based on

it 2800º temperature rating and real synthetic formula.

#6

Assemble per recommended O.E. procedures, using new

brake hardware, then test drive the vehicle. VERY

IMPORTANT: Initially make about 20 to 30 ultra light

pedal "slow downs" from 30 mph to 5 mph but

do not completely "stop" the vehicle. Next make 20 to 30

"medium pressure stops" from 30 mph, but not panic style

or hard pedal pressure.

Be sure

to allow about

1 to 2

minutes for cool down between each slowing down cycle. This is critical because it allows the rotors and

pads to adjust to each other and for embedded

temperature increases to bleed off. This break in

procedure may seem extreme to some technician, but this

is the "only" way to properly burnish a new set of pads

to a rotor... intense dyno and road testing has proven

it.

(Be sure to

tell customers no panic stops for at least 300 miles,

the actual average time of the "real burnish period".

This light and then heavier slow down procedure, properly

burnishes the Silencer's micro-fine particles into the

friction surfaces and conditions (softens) the burnish

process. The goal is to slow down the

burnish and control the pressures and higher burnish

temperatures new pads are exposed to, for the

longest period of time. The hotter and harder a

pad is pushed during its break in period (post cure) the

harder it becomes (referred to as shore number) and therefore the worse the

performance. There are several laboratory measurements

in our industry, including FEI (Friction Energy Index),

Coefficient of Friction, D3EA, (Multi Variable Dyno

Evaluation), BEEP (Brake Effectiveness Evaluation

Procedure), Torque, etc. used to determine friction

performance. By using GWR's five steps plus burnish and products, you

will improve a vehicles test numbers by up to 8%. This

proves to be not only a better feeling, noise free pad...

but the vehicle actually stops shorter and is safer.

.gif)

.jpg)